Architectural textured walls, brought to life through integrated illumination

Architectural textured walls, brought to life through integrated illumination

Designed by M|R Walls. Illuminated by Applelec Light Engines.

Parametric Walls transform architectural surfaces into sculptural features — combining fluid, nature-inspired geometry with precision-engineered illumination. Designed by world-renowned designer Mario Romano of M|R Walls and manufactured in the UK, each installation is created as a seamless, expressive surface rather than a collection of repetitive tiles.

Designed by M|R Walls and manufactured in the UK, Parametric Walls can be specified through Applelec Interiors as a complete illuminated wall solution — with Corian® Solid Surface supplied by CDUK and illumination engineered and manufactured by Applelec Lighting.

Architectural surfaces, engineered for scale

Unlike traditional decorative wall systems, Parametric Walls are conceived as architectural elements. Each surface is digitally modelled and precision-manufactured to create flowing, continuous forms that scale naturally across walls of any size.

Inspired by organic patterns found in landscapes, geology, and natural movement, the collection delivers depth, rhythm, and visual impact without visible repetition — allowing walls to expand, wrap, and evolve organically within a space.

Engineered illumination, designed to perform

At the heart of every illuminated Parametric Wall is Applelec Lighting’s expertise in designing and manufacturing bespoke backlighting systems.

Rather than treating lighting as an add-on, illumination is engineered specifically for each pattern, scale, and application. This ensures controlled, even light that enhances depth, shadow, and surface geometry — elevating the wall from a static material into an immersive design feature.

While Parametric Walls can be installed unlit, Applelec Interiors specialises in delivering the complete illuminated solution, ensuring performance and visual quality are resolved as one.

.jpg)

Non-repetitive design, without limits

Parametric Walls use a patented puzzle-piece construction developed by M|R Walls. Each section is CNC-machined to interlock precisely, creating a continuous surface with no repeating tiles or visual breaks.

This approach allows designers to work at true architectural scale, removing the constraints of repetition while maintaining consistency and precision. Despite their complex appearance, panels are engineered for efficient installation, combining creative freedom with practical confidence.

Architectural material, proven performance

Parametric Walls are manufactured from architectural-grade Corian® Solid Surface, selected for both its design versatility and technical credentials.

-

Non-porous, hygienic, and low maintenance

-

Durable and suitable for demanding interior environments

-

Class A fire rated

-

Translucent and ideal for illuminated applications

When paired with Applelec’s bespoke backlighting systems, Corian® Solid Surface allows light to interact beautifully with surface geometry — highlighting contours and delivering a refined architectural glow.

Corian® Solid Surface

CDUK has curated a range of five Corian® Solid Surface colours to complement the twelve M|R Walls designs and guarantee the material’s suitability across a range of applications.

The Core Collection

The Parametric Walls Core Collection features twelve nature-inspired patterns, each designed to create flowing, sculptural surfaces without visible repetition. Patterns range from soft, organic forms influenced by water and foliage to more structured, geometric expressions. Every design is built using the same patented construction technique, allowing surfaces to scale seamlessly across walls of any size.

.jpg)

Bespoke by nature

Beyond the core collection, Parametric Walls offer complete creative freedom.

Layouts, scale, pattern flow, material selection, and illumination are all developed in response to each project brief. Bespoke patterns and project-specific solutions can be created in collaboration with the design team, allowing truly individual architectural features to be realised.

Every installation is developed as a complete system — tailored, engineered, and manufactured to support the overall design intent.

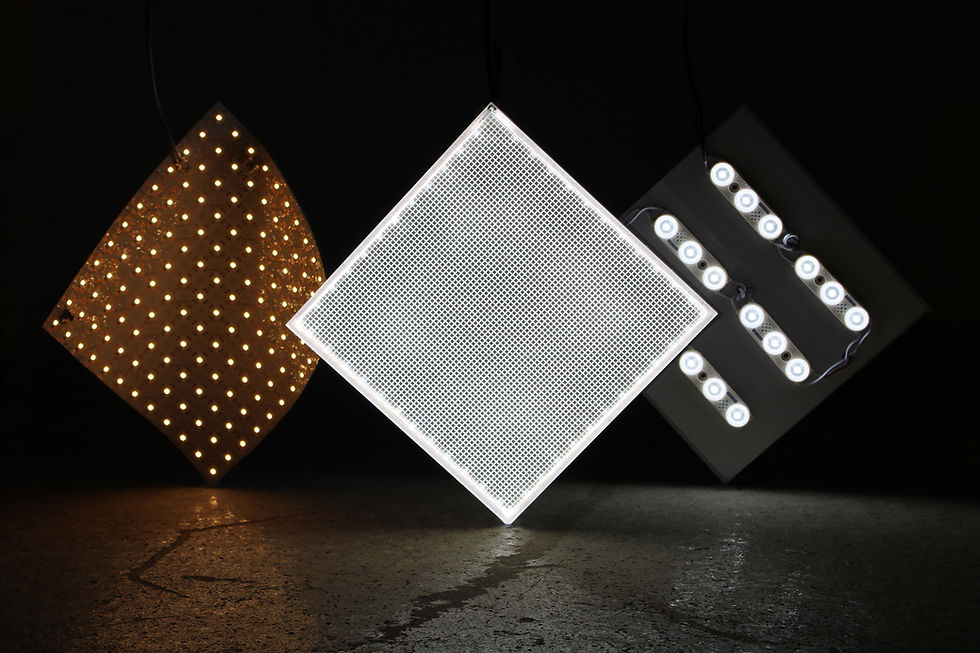

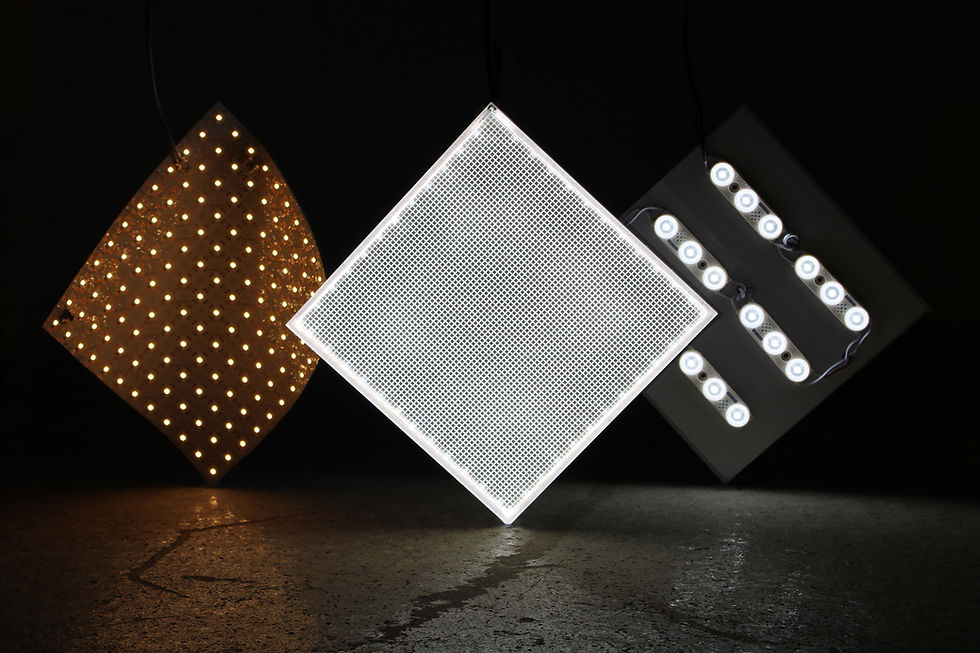

Where light becomes part of the surface

Integrated illumination is engineered into every Applelec Interiors solution from the outset. Rather than relying on a single lighting format, we draw on Applelec’s extensive manufacturing experience and long-standing LED partners to engineer the most appropriate illumination solution for each surface and application.

Illumination may be delivered using a range of tried and tested backlighting approaches — from Applelec LED Light Sheet (now TM66 rated 2.7) to a number of LED solutions, selected to suit the depth, scale, material translucency, and performance requirements of the project. LED options include Grade A, DC-approved high-efficiency, tuneable white, RGBW, addressable, high-CRI LEDs and more.

Integrated into a bespoke lightbox structure, Applelec Light Engines support the surface and house the illumination, delivering discrete to no visible framing from the front. Each solution is engineered as a complete, ready-to-spec and install system, drawing on Applelec’s decades of experience in manufacturing architectural lighting, bespoke trade signage fabrication, and LED distribution.

Where light becomes part of the surface

Integrated illumination is engineered into every Applelec Interiors solution from the outset. Rather than relying on a single lighting format, we draw on Applelec’s extensive manufacturing experience and long-standing LED partners to engineer the most appropriate illumination solution for each surface and application.

Illumination may be delivered using a range of tried and tested backlighting approaches — from Applelec LED Light Sheet (now TM66 rated 2.7) to a number of LED solutions, selected to suit the depth, scale, material translucency, and performance requirements of the project. LED options include Grade A, DC-approved high-efficiency, tuneable white, RGBW, addressable, high-CRI LEDs and more.

Integrated into a bespoke lightbox structure, Applelec Light Engines support the surface and house the illumination, delivering discrete to no visible framing from the front. Each solution is engineered as a complete, ready-to-spec and install system, drawing on Applelec’s decades of experience in manufacturing architectural lighting, bespoke signage fabrication, and LED distribution.